ASi-5 Drive Solutions for Danfoss

The Danfoss frequency inverters are connected to ASi via their standard RS485 interface. The ASi-5 motor module BWU4980 with the two wires is simply connected to the RS485 terminals in the Danfoss VLT frequency inverter and that’s it. A single cable is used for power supply and communication. The module is suitable for the following frequency inverters in the Danfoss VLT series:

- VLT AQUA Drive FC 202

- VLT AQUA Drive FC 302

- VLT Decentral Drive FCD 302

- VLT Midi Drive FC 280

- VLT HVAC Basic Drive FC 101

Please contact us if the drive you are looking for is not listed here. Here you will find detailed information about the advantages of our AS-Interface drive solutions.

ASi-5 Module for Danfoss VLT frequency inverter

The new ASi-5 Motor Module for frequency inverters from the Danfoss VLT series (BWU4980) makes use of ASi-5 to change process control ramps and speed cyclically, thereby enabling extremely quick adjustment. An optimized process data image is provided for this purpose. Motor feedback is also very comprehensive thanks to ASi-5. This is because in addition to the error flags, even the current consumption of the motor and additional information are available for evaluation in the cyclic input data.

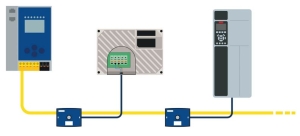

Fig.: With the ASi-5 motor module BWU4980, Danfoss VLT frequency inverters can be put into operation quickly via plug-and-play.

Save time and costs, avoid parameterization errors

The ASi-5 motor module (BWU4980) will, of course allow you to benefit from the well-known ASi advantages, such as drastically reduced wiring complexity. Yet another advantage is gained from the use of our Bihl+Wiedemann Software Suite: Once you have configured an ASi-5 motor module and stored the parameters of the used Danfoss frequency inverters, you can simply copy this information to numerous other ASi-5 motor modules. During commissioning, all motor parameters are downloaded automatically. Parameterization also takes place automatically when motors and motor modules are replaced. This saves you plenty of time plus costs while preventing potential parameterization errors.

Your advantages at a glance

- One Danfoss VLT frequency inverter can be controlled per module

- Detailed diagnostics incl. active current

- Cyclic writing of speeds and ramps in 1.27 ms

- Acyclic writing of Danfoss parameters

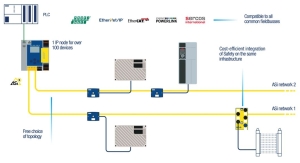

Fig.: More than 100 Danfoss VLT frequency inverters can be efficiently wired on just one Ethernet node.