Bihl+Wiedemann provides optimal conditions for implementing Industry 4.0 at field level. For a successful implementation of Industry 4.0 projects, it must be ensured that systems, machines and assembly lines communicate permanently with each other. This communication generates huge amounts of data at sensor level. A powerful data shuttle is needed to evaluate them.

That is where Bihl+Wiedemann ASi-5 finds its use: the latest generation of the standardized AS-Interface fieldbus system offers a high data bandwidth and short cycle times. It makes it easy to integrate intelligent sensors such as IO-Link, which are so important for Industry 4.0 and smart factories. Bihl+Wiedemann ASi-5 gateways transmit the sensor data to the IT via OPC UA. There they become valuable information, without which Industry 4.0 projects or predictive maintenance would not be implementable.

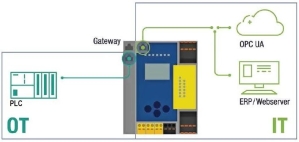

How to use an ASi-5/ASi-3 gateway as an edge device to send data to the cloud is described here.

As an “edge device”, the ASi Gateway forms the interface between IT and OT. The connection to a control system (Operational Technology) is made via the fieldbus interface. Diagnostic data and other IT-relevant data are transmitted in parallel via the diagnostic interface by means of OPC UA.

High data bandwidth with Bihl+Wiedemann ASi-5 devices

ASi-5 – the latest generation of the standardized AS-Interface fieldbus system – boasts high data bandwidth and short cycle times. The evolution of ASi can be compared with the bandwidth increase of the Internet. For example, new Bihl+Wiedemann ASi-5 nodes can cyclically transmit up to 32 bytes of I/O data per node: in 1.27 ms, ASi transmits a total of up to 8 bytes pernode. The advantage is that besides the cyclic data, even other data such as parameters and diagnostics can be transported. The data bandwidth of ASi-5 is therefore sufficient even for demanding applications. Bihl+Wiedemann ASi devices also provide valuable data as intended in Industry 4.0. The interesting data comes from the connected sensors, but they are connected to the Bihl+Wiedemann gateways via ASi. The gateways also provide additional diagnostic data. Thanks to them, any faults, such as a cut cable, can be quickly found and rectified.